Get Beyond the Noise:

Validated High-Selectivity Thermal Runaway Detection

Independent Performance Verification by the National Research Council Canada

Integrative Nanotech Sensor Performance Distinguishes Passive Venting from Thermal Runaway

Audience: Automotive OEMs and Battery System Integrators

December 2025

Executive Summary

In electric vehicle (EV) and BESS safety, fast detection matters, but only if the signal is true. Selectivity turns rapid detection into reliable protection.

Independent testing by the National Research Council Canada (NRC) confirms that Integrative Nanotech’s (INT’s) proprietary gas sensor technology uniquely differentiates benign cell venting from catastrophic thermal runaway (TR).

By contrast, leading commercial sensors misidentified safety venting events as a critical failure—producing false positives that could trigger unnecessary shutdowns, costly interventions, and reputational risk for energy storage owners, and battery system integrators alike.

This white paper summarizes the NRC’s test methodology and findings, demonstrating how INT’s sensors provide battery management systems (BMS) with deterministic, actionable signals required for modern EV safety.

Why False Positives Matter

Global regulations (UNECE GTR#20) require rapid detection and passenger alerts during thermal runaway. However, lithium-ion cells often undergo benign, passive, venting which acts as a safety mechanism for internal pressure-relief and does not require emergency intervention. This distinction is equally critical for BESS, where misinterpreting routine venting as a critical event can trigger costly, unnecessary system shutdowns.

Most commercial sensors struggle to distinguish:

Passive Venting: A maintenance event; log only

Thermal Runaway: A critical safety hazard requiring immediate intervention

Misclassifying venting as runaway triggers unnecessary destructive countermeasures, and costly downtime. For OEMs and System Integrators, this leads to unjustified warranty claims and brand reputational risk.

True selectivity is not optional – it is essential to safe and cost-efficient EV and BESS operation.

How the NRC Tested the Sensors

The NRC’s Battery System Integration and Optimization Laboratory evaluated INT sensors using two automotive-standard 21700 cell chemistries:

LFP (Lithium Iron Phosphate): Lower reactivity

NMC (Nickel Manganese Cobalt): Higher energy density/reactivity

Photograph of both cells used in test: Hakadi LFP cell (Purple) and Samsung 50S NMC cell (Green).

Sensor test configuration: Integrative Nanotech (“A” top), and two leading sensors (“B” middle and “C” bottom).

Cells were heated to induce both passive venting and full thermal runaway. INT’s sensor “A” was tested alongside two leading commercial sensors “B” and “C”, with all signals synchronized to video, FTIR and multi-gas instrumentation.

Key Findings: Specificity and Speed

The NRC’s test concludes that leading commercial sensors “B” and “C” struggled with ambiguity between simple venting and catastrophic thermal runaway. In contrast, the INT sensor provided clear, actionable signal differentiation: a deterministic “on-off” response that is essential for safe BMS automation.

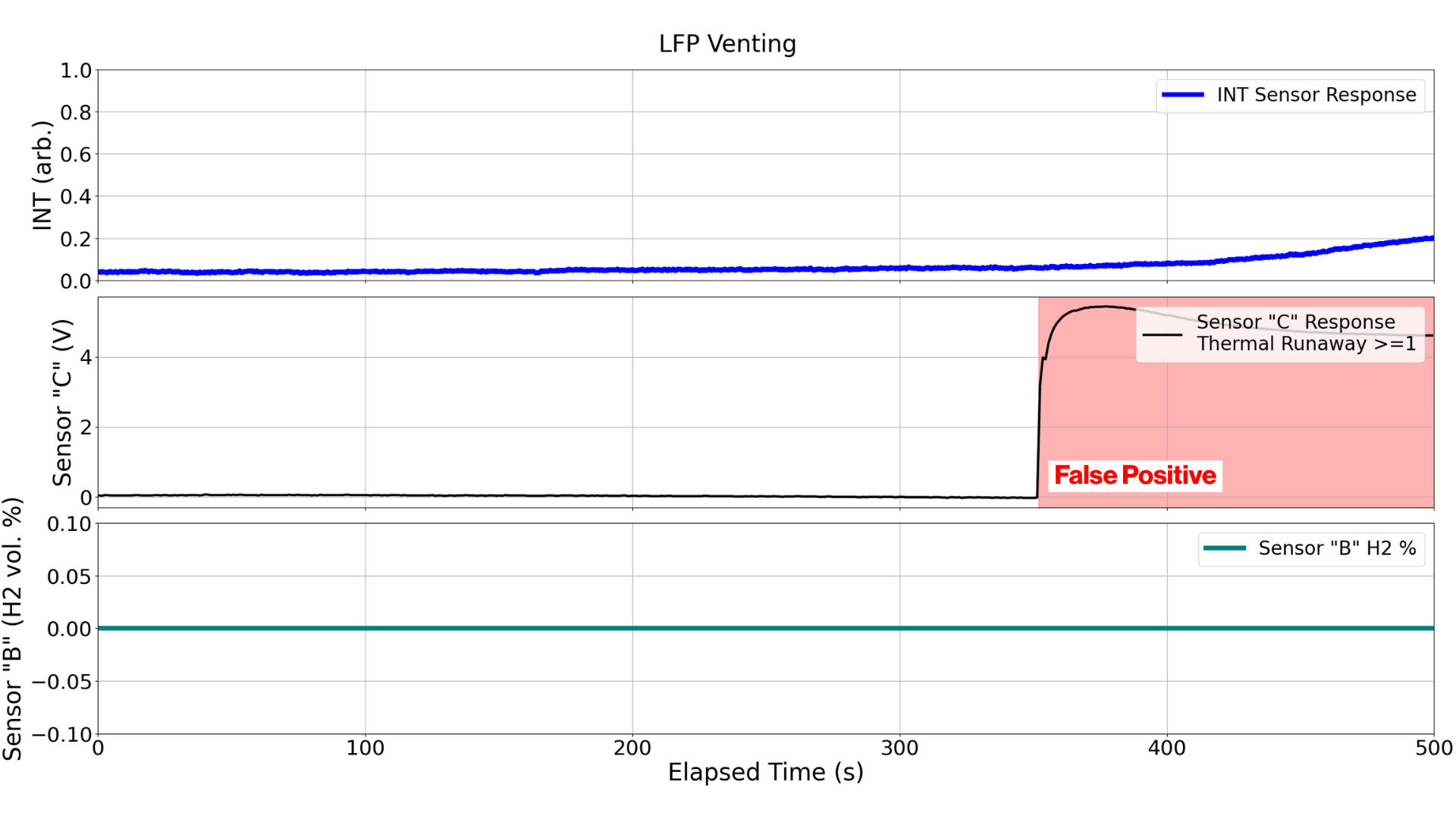

Elimination of False Positives (Selectivity)

During passive venting:

Commercial sensor “C” showed a rising signal consistent with a false thermal runaway alarm.

INT sensor “A” showed minimal, stable response and correctly ignored non-critical venting.

NRC Observation: "The [“C”] sensor... would result in false positives... In contrast, INT proprietary sensors [showed] minimal response during venting."

INT (top), “C” (middle), and “B” (bottom) responding to LFP venting. “C”'s sensor showcases a false positive from ~350 seconds onwards.

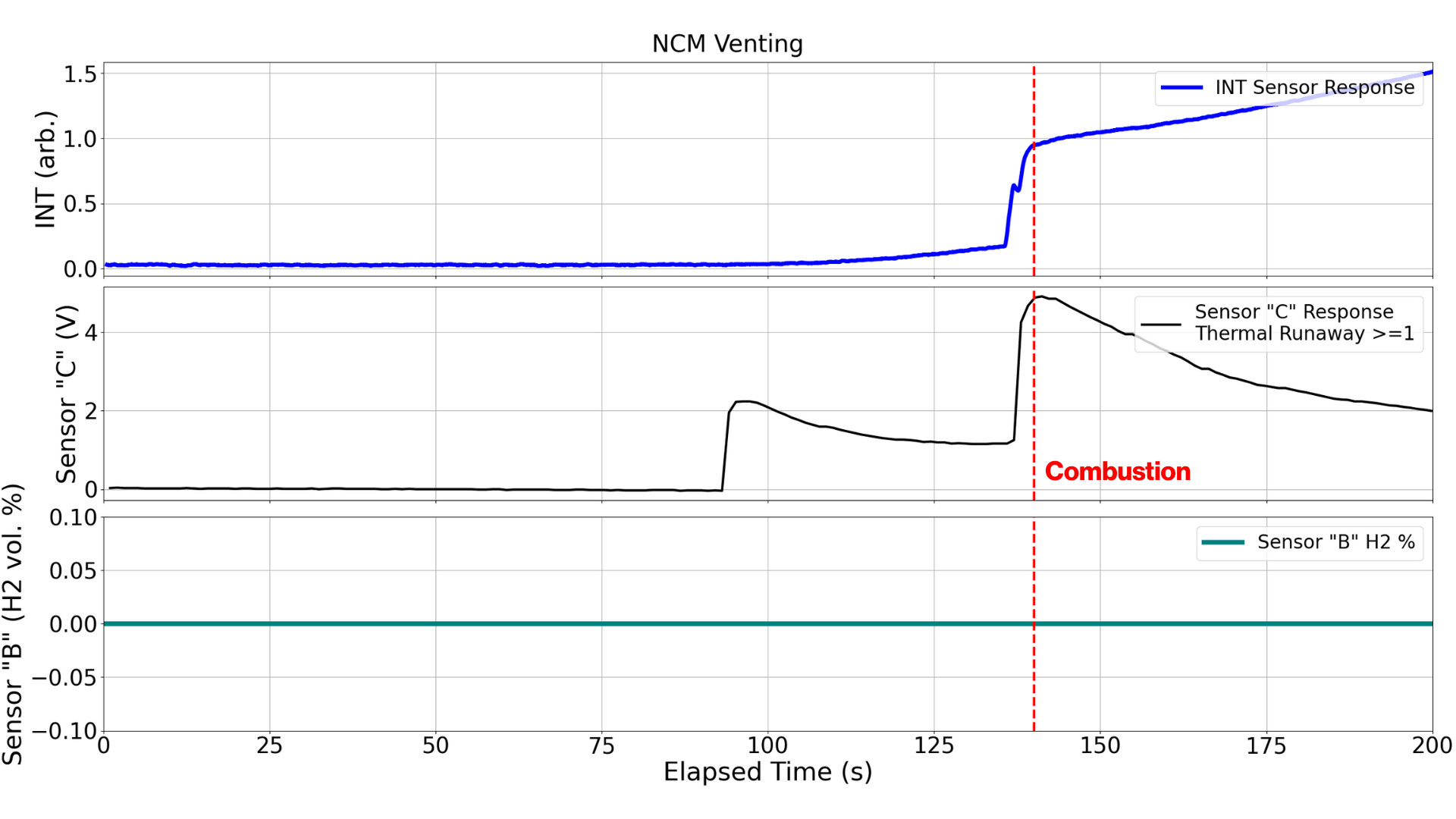

Fast, Deterministic Thermal Runaway Detection

During induced thermal runaway:

INT reacted immediately to combustion events

INT remained stable during prior venting, preserving signal clarity.

Across LFP and NMC tests INT produced clean, deterministic detection events.

The tested leading commercial sensors exhibited ambiguous patterns due to earlier false positives.

INT (top), “C” (middle), and “B” (bottom) responding to NMC venting. In this trial combustion products formed, and ignition occurred around 140 seconds. INT sensor showed negligible response to venting but quickly responded when combustion products were created. The early response from “C” is uncertain due to previous false positives during normal venting.

Battery Chemistry Agnostic

The INT sensor was consistent across both tested chemistries:

LFP: Ignored venting; detected thermal runaway.

NMC: Withstood venting; reacted instantly to combustion.

Data Spotlight: The Signal Difference

NRC note to industry stakeholders:

"[INT’s] specificity is particularly important… since they would trigger very different responses for the users."

Conclusion

NRC’s independent evaluation confirms that Integrative Nanotech’s sensor delivers next-generation thermal runaway detection:

Stable during venting. Instantaneous during hazard. Zero false positives.

Key Takeaways for OEMs and System Integrators:

Improved safety automation

Maximize asset uptime

Lower liability and compliance risk

Next Steps for Your Team

To access the raw NRC signal data, review the specific sensor models, or discuss INT integration with your battery system:

Contact Integrative Nanotech: solutions@integrativenanotech.com